CerMark Laser Marking Materials

The CerMark laser bonding process was invented because some material types are not easy to laser mark with with good contrast.

The patented CerMark process has been the industry standard for 25 years. CerMark has been tested and approved by all branches of the US military, NASA, commercial aerospace companies and medical device manufacturers.

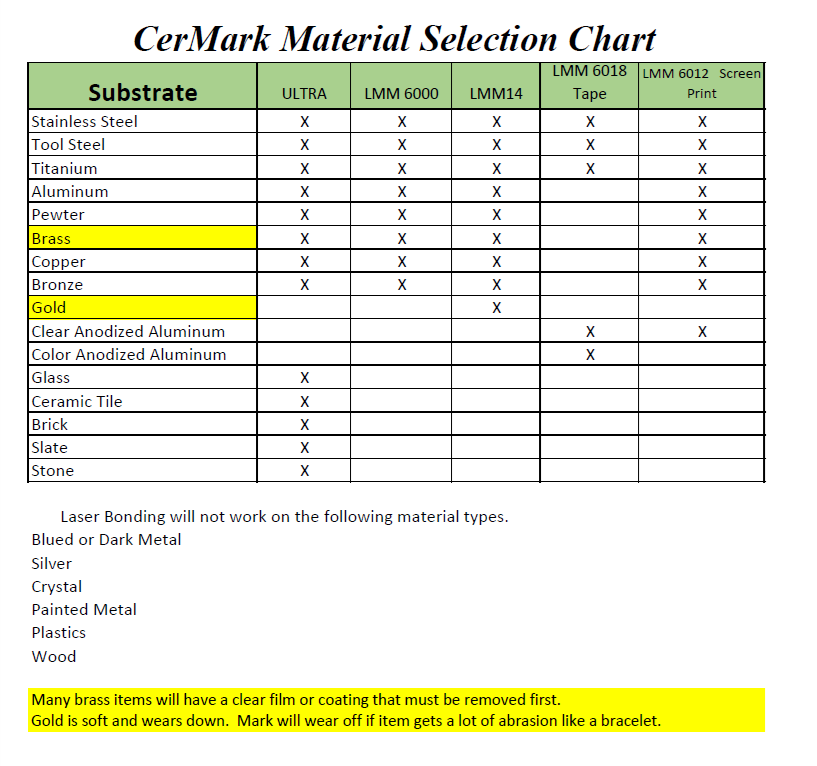

There are a few different versions of so please review the material selection chart below which can help you select the CerMark version best suited for your application.

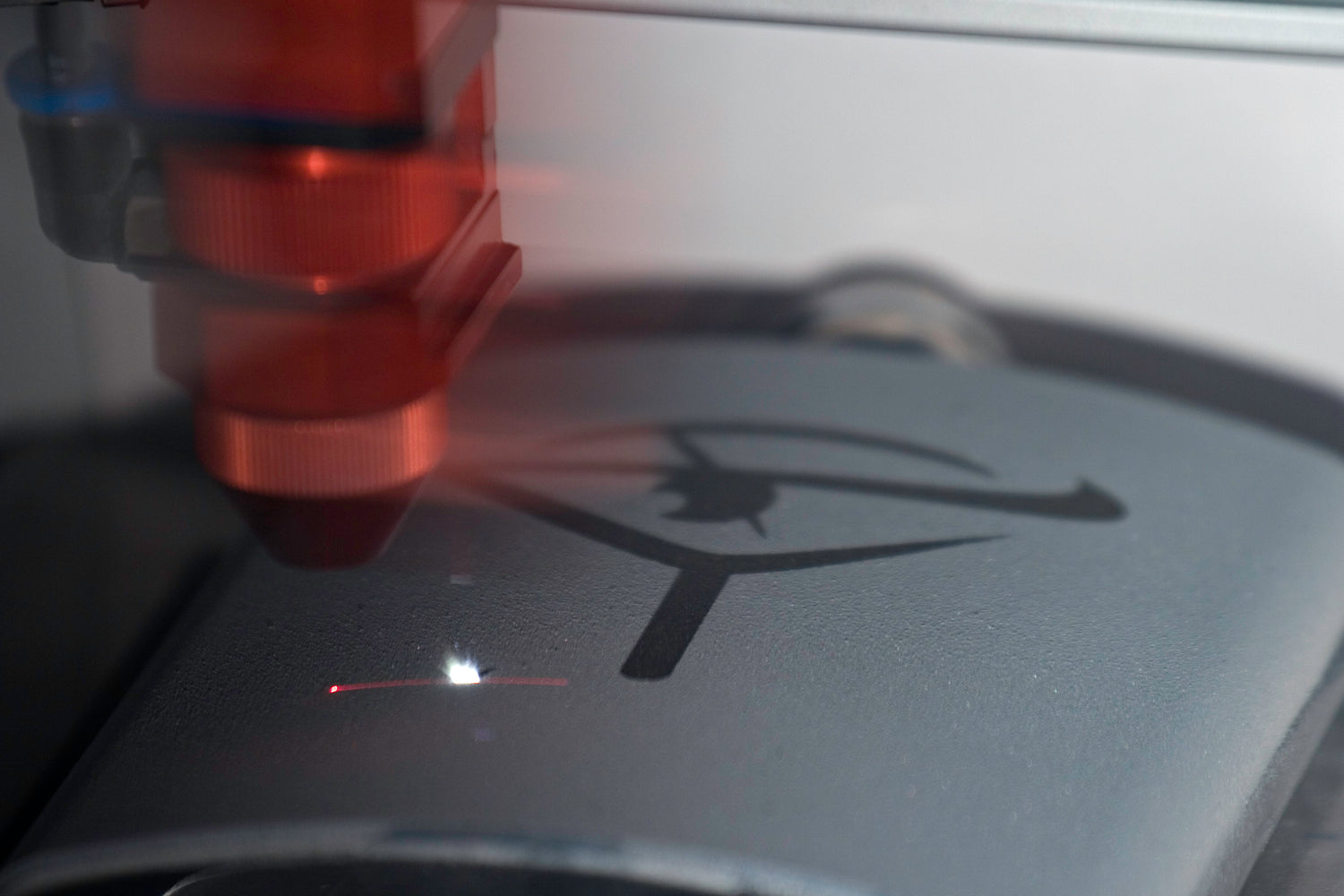

The CerMark laser bonding process.

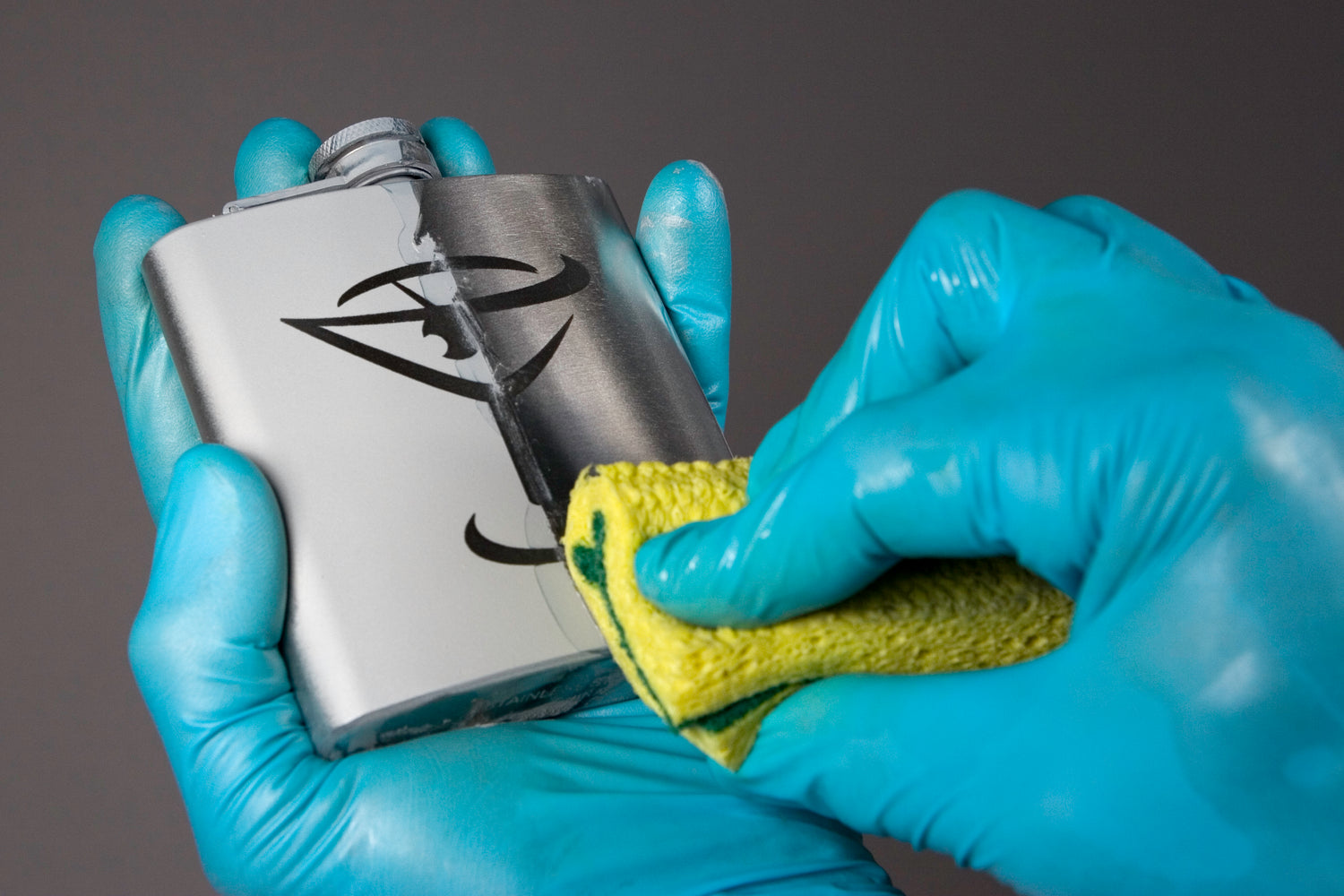

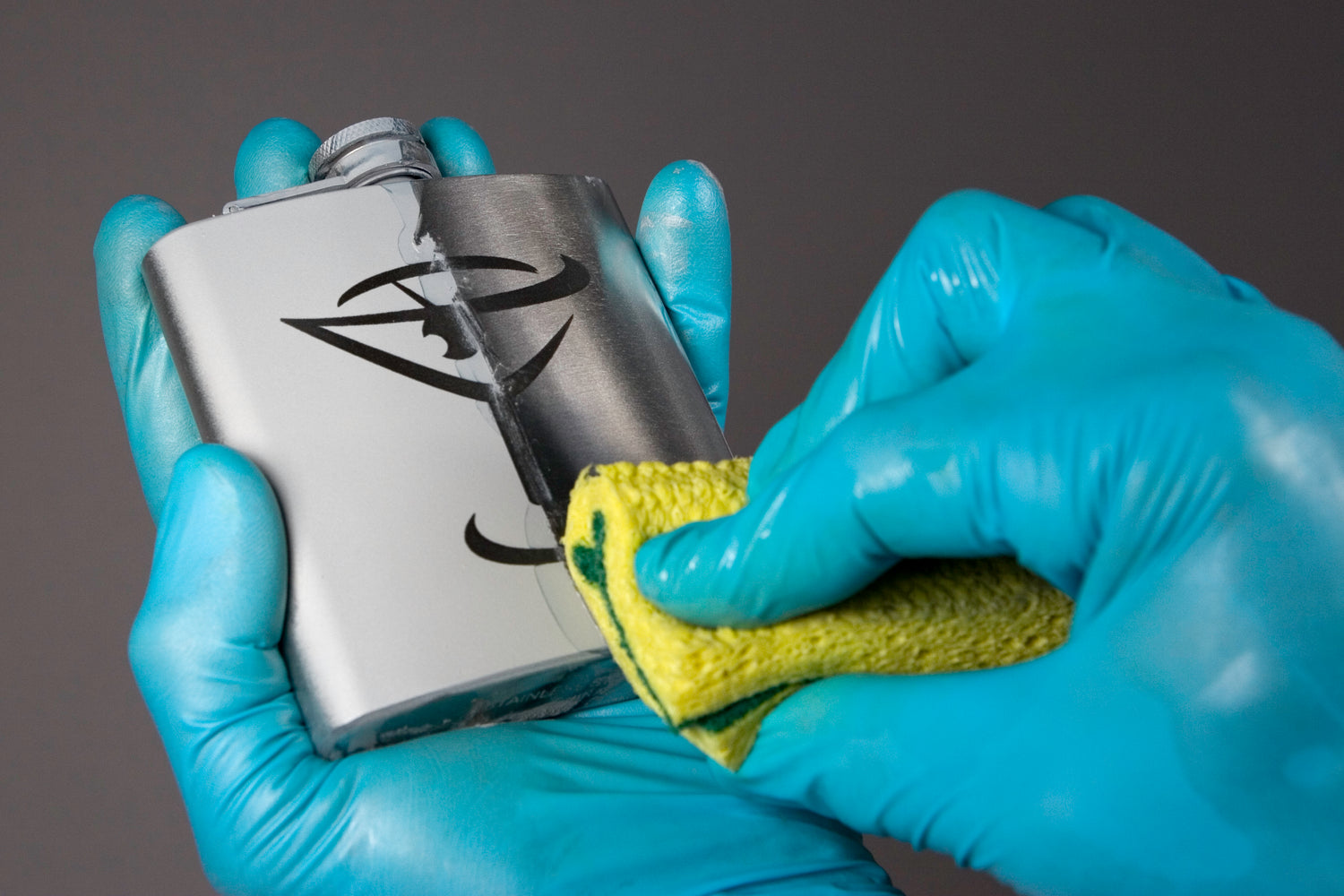

Apply a thin layer of CerMark to the item and let it dry. Laser mark with CO2 or Fiber laser and wash the excess off. (Fiber lasers must be set at 200 kHz. or higher frequency.) Since all lasers have different output based on age and optics it is important to test for your specific laser proper settings. See our Technical Support Pages for details.

CerMark Versions

-

CerMark LMM 6000 Metal Marking Material

This is the most commonly used version of CerMark that has been...

-

CerMark Ultra for Metals, Glass and Ceramic Items

This coating is formulated to work on many typical laser markable hard...

-

LMM 14 Metal Marking Material

LMM 14 laser marking material is used to create permanent black marks...