New CerMark Ultra

Share

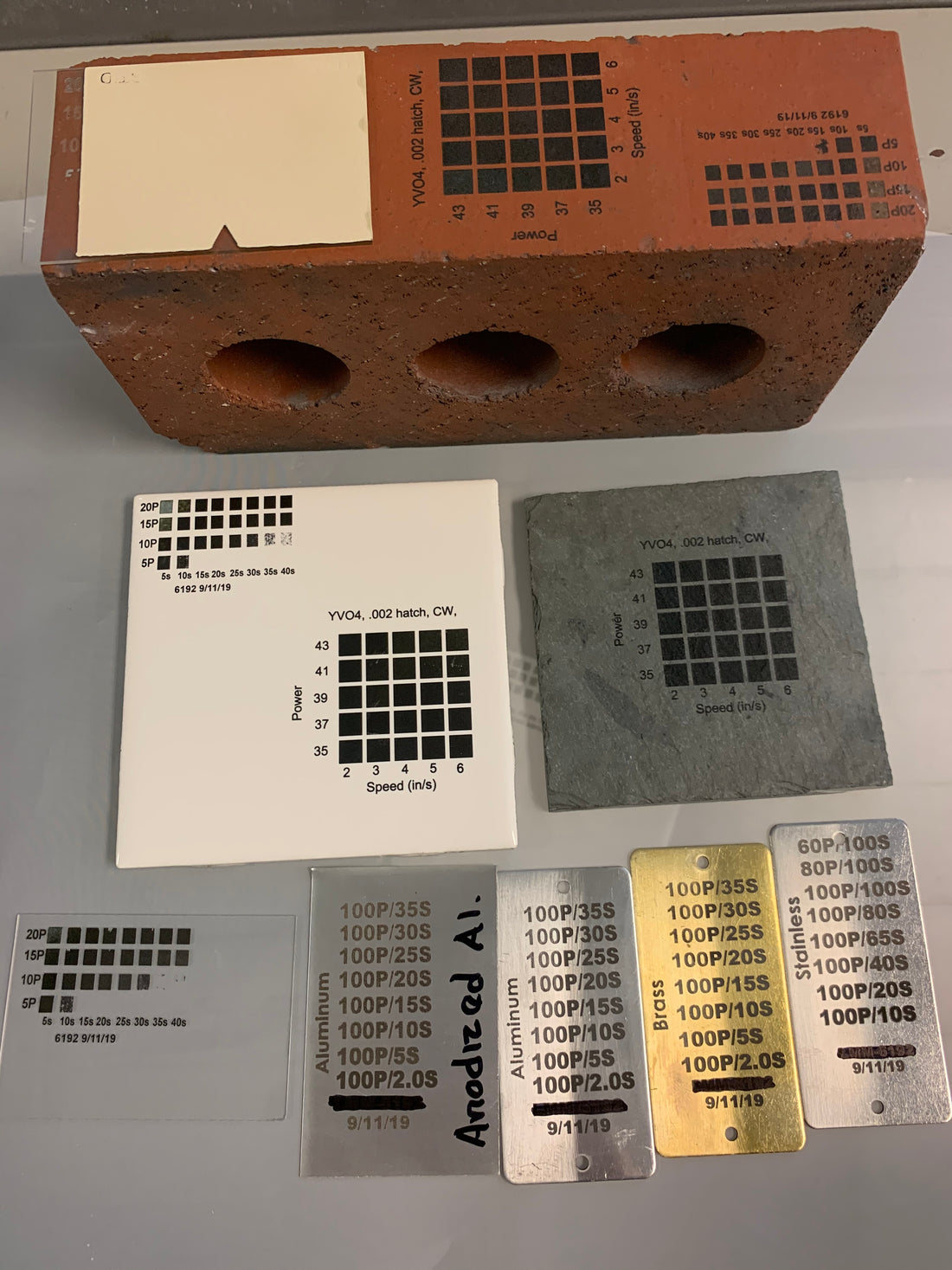

The CerMark Research & Development team is pleased to announce the approaching release of their new CerMark coating. This new product is formulated to work on all typical laser markable hard surfaces such as metals, glass, ceramics (glazed or unglazed), stone, brick (glazed & unglazed), slate and more. This formula is not intended for painted items, wood or plastics.

The new laser marking material will raise the bar considerably for laser bonding speed, versatility, quality and durability.

Fastest marking speed possible

Preliminary testing shows many customers should be able to mark stainless steel with their laser system set at 100% marking speed with only needing as little as 40 watts of CO2 power. This coating will also create deep black marks at a very wide range of laser power and speed settings.

Much improved glass marking

There is a much greater ease of glass marking at a wider range of settings and much less coating thickness will be required.

Same application/handling qualities as CerMark LMM-6000

The liquid version can still be thinned with alcohol based liquids to allow for fast drying time. The dilution ratios will remain the same as LMM-6000 and LMM-14, 1:1 for spraying and 2:1 for brush on applications. Once dry it will not rub off on your fingers while handling it. This will allow you to coat items and box or stack them for marking at a later date.

No hard settling

Formulated to eliminate clumping in liquid form and spray cans which allows for easy mixing before use.

Improved spray can design

A new specially designed valve system will be introduced as part of the new coating spray can allowing for better performance and eliminating the need to store can upside down.

Will not stain (tarnish) sensitive metals

Will not stain or tarnish sensitive metals such as brass, copper, and some other forms of steel.

The new CerMark product should be available Q1 of 2020 in both aerosol & liquid providing a variety of application methods for our customers.